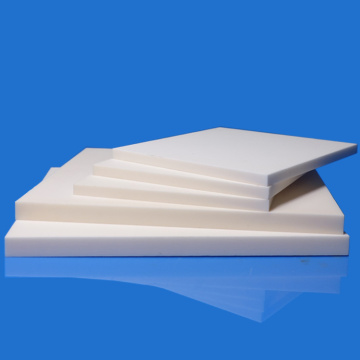

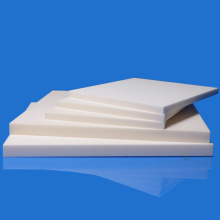

High Purity 99% 99.5% Alumina Ceramic Setter Plates

| Min. Order: | 10 Piece/Pieces |

|---|

| Packaging: | Export carton |

|---|---|

| Productivity: | 100,000pcs/month |

| Brand: | Jinghui ceramics |

| Transportation: | Ocean,Land,Air |

| Place of Origin: | China |

| Supply Ability: | 500,000pcs/month |

| Certificate: | RoHS,REACH |

| HS Code: | 8547100000 |

| Port: | Shenzhen Port,Hongkong Port |

Basic Info

Model No.: Standard size or customized available

Click on the follow link to find out more information: https://www.ceramictek.com/industrial-ceramic-plate/

Company Info

- Company Name: Jinghui Industry Ltd.

- Representative: Saiwu Tan

- Product/Service: Metallized ceramics , Precision ceramics , Pepper Grinder Mechanism , Ceramic Grinding Mechanism , Alumina Ceramic Plate , Ceramic Substrate

- Capital (Million US $): 5,000,000RMB

- Year Established: 2008

- Total Annual Sales Volume (Million US $): US$5 Million - US$10 Million

- Export Percentage: 71% - 80%

- Total Annual Purchase Volume (Million US $): Below US$1 Million

- No. of Production Lines: 10

- No. of R&D Staff: 5 -10 People

- No. of QC Staff: 11 -20 People

- OEM Services Provided: YES

- Factory Size (Sq.meters): 10,000-30,000 square meters

- Factory Location: ZhongLian Village, LengShuiJiang City, Loudi, Huanan

- Contact Person: Mr. Andy Chen

- Tel: +86-755-26759158

Premium Related Products

Other Products

Hot Products

High Temperature Resistant pet Industrial tape for fixure protection insulation useWater sensitive destructible vinyl eggshell sticker paper material, water authenticating eggshell label material2015 high anti fake technology with Miniature text authenticity QRcode hologram stickerdouble sided adhesive security tamper evident VOID OPEN tape for security bag sealingtamper evident security tape for security bag sealingAdhesive UV ink printed anti-fake hologram label stickerCustom anti-fake Holographic 3d laser Hologram eggshell stickerCustom self adhesive security tape, tamper evident security void tape with perforation line and serial numberNon residue tamper evident label 3m adhesive sticker material warranty void label material roll for automotive sectorsCustom 3D logo security hologram wine label holographic security wine stickerShenzhen ZOLO high quality viynl stickershigh quality anti-counterfeit laser fish stickerChina anti-counterfeit tamper evident security void custom label printing materialCustom Sticker Usage and Vinyl Material lolgo label sticker vinyl label printing stickerCommercial Use Customized QR Code Sticker Printing & Security Warranty Void Paper StickerGood quality waterproof blank adhesive thermal label sticker for blood bag